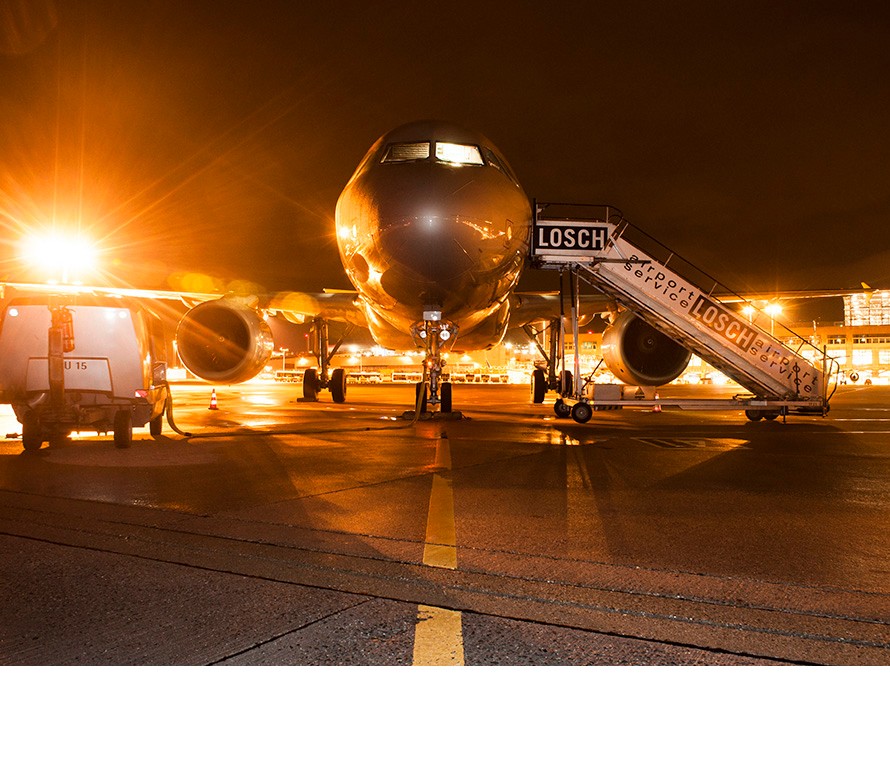

Losch Airport Service saves up to 60% energy at Stuttgart airport by using an electric vehicle fleet

Turning point in the apron areas of Stuttgart airport: Losch Airport Service carries out almost 100% of all handling jobs in an emission-free way. The environmental research institute Öko-Institut e.V. has coached this transformation and calculated energy savings for individual vehicles of up to 60 percent.

This innovative service provider is now using 14 electrically driven tugs for transportation of luggage trolleys, passenger staircases and ground power units, the luggage is loaded and unloaded with the help of electric conveyors, and electric StreetScooters are used for aircraft cabin cleaning. With this vehicle fleet, Losch Airport Service sets the benchmark on a Federal scale, too.

Electromobility significantly simplifies everyday work

The Losch employees also welcome this transition towards an electric vehicle fleet. According to reports of Öko-Institut, the low noise exposure and the significant reduction of emissions are making everyday work significantly easier.

The route towards emission-free handling services started for Losch as early as in 2014, when the enterprise used an electric tug, for the first time. The last hybrid tug was put out of service in 2018. Without exception, Losch now moves all luggage trolleys, passenger staircases and ground power units, which are required as a terrestrial power supply for the aircrafts, with its 14 electric tugs.

From trial to daily practice

Support for this ambitious project of Losch – aiming for an entirely emission-free aircraft handling – came from the German Federal Ministry for the Environment, Nature Conservation and Nuclear Safety (BMU). The ministerial funding project, which the family business Losch carries out in cooperation with Stuttgart airport and Öko-Institut, is called “Scale-up”. Scale-up recently enabled Losch to extend their vehicle fleet with four electric tugs and, at the same time to address a new project: the replacement of Diesel-driven conveyor belts. The objective of the trial at Stuttgart airport is to jointly gain knowledge and to share it among all partners. Two competitors have bundled their knowledge and experience in terms of electromobility. That’s a first in Germany. But it also goes in line with the objective of this project: After a comprehensive strategy development with respect to economic and ecological consequences, the partners want to initiate a dialogue with other airports for the purpose of communicating this knowledge and discussing opportunities of its transfer.

Impressively low carbon footprint

The research institute Öko-Institut demonstrates in an interim result of its report, that the electric apron buses of Stuttgart airport already cause about a quarter, and the electric tugs in the apron areas about a fifth less CO2 emissions, compared with their respective diesel counterparts. These figures were established using the approach of the German average mix for power generation over the entire life cycle (including manufacture and disposal). Furthermore, the institute calculated that the apron fleet electrification within the scope of the aforementioned project only increases the overall power demand by a one-digit percentage.

The institute expects that these benefits will further increase in the course of the progressing decarbonisation of the public power system. If the current location mix for Stuttgart airport is assumed, greenhouse gas emissions are already today about one lower with electrically operated vehicles than with comparable diesel vehicles. For 2019, Losch expects another significant reduction of CO2 emissions: the conveyor belts, which have only been replaced in the second half of 2018, will then also come into effect in its environmental balance.

Handling completely free from emissions

But apart from the Scale-up project, Losch makes the transition towards electric vehicles in other areas too. The company has, for instance, completely abandoned the use of petrol or diesel engines for driving their cabin cleaning personnel to the aircrafts and back to the building. The employees use a total of five StreetScooters to make their way to the aircrafts of Losch clients like Tuifly, Eurowings or Condor. StreetScooters are fully electric small vans, which are manufactured by a subsidiary of Deutsche Post. Two Nissan eNV200 complete the electric vehicle fleet for the apron areas.

“Handling completely free from emissions is no longer a vision for the future. I’m, happy that we could make a not insignificant contribution towards the big objective “Fairport Stuttgart” with this project. I would also like other service providers to join the initiative towards electric vehicles. It is an exciting journey towards this goal, which is not always easy, but every eco-friendly metre counts for us: for our employees at the aprons, for the environment, and for the expertise in our company,” summarised Marc Losch.

The full publication of the Eco-Institute can be found at:

https://www.oeko.de/fileadmin/oekodoc/WP-scale-up.pdf